Get in touch with us:

+49 5151 1040

info@reintjes-gears.de

Service Hotline

+49 5151 104104

REINTJES GmbH

Eugen-Reintjes-Straße 7

31785 Hameln

Or use our contact form:

Our next trade fair dates

03/10/2026 to 03/11/2026

TTB

Mobile, US

03/25/2026 to 03/27/2026

Asia Pacific Maritime

Singapore

04/22/2026 to 04/24/2026

NN Logistica

Manaus, Brazil

04/22/2026 to 04/24/2026

Sea Japan

Tokyo, Japan

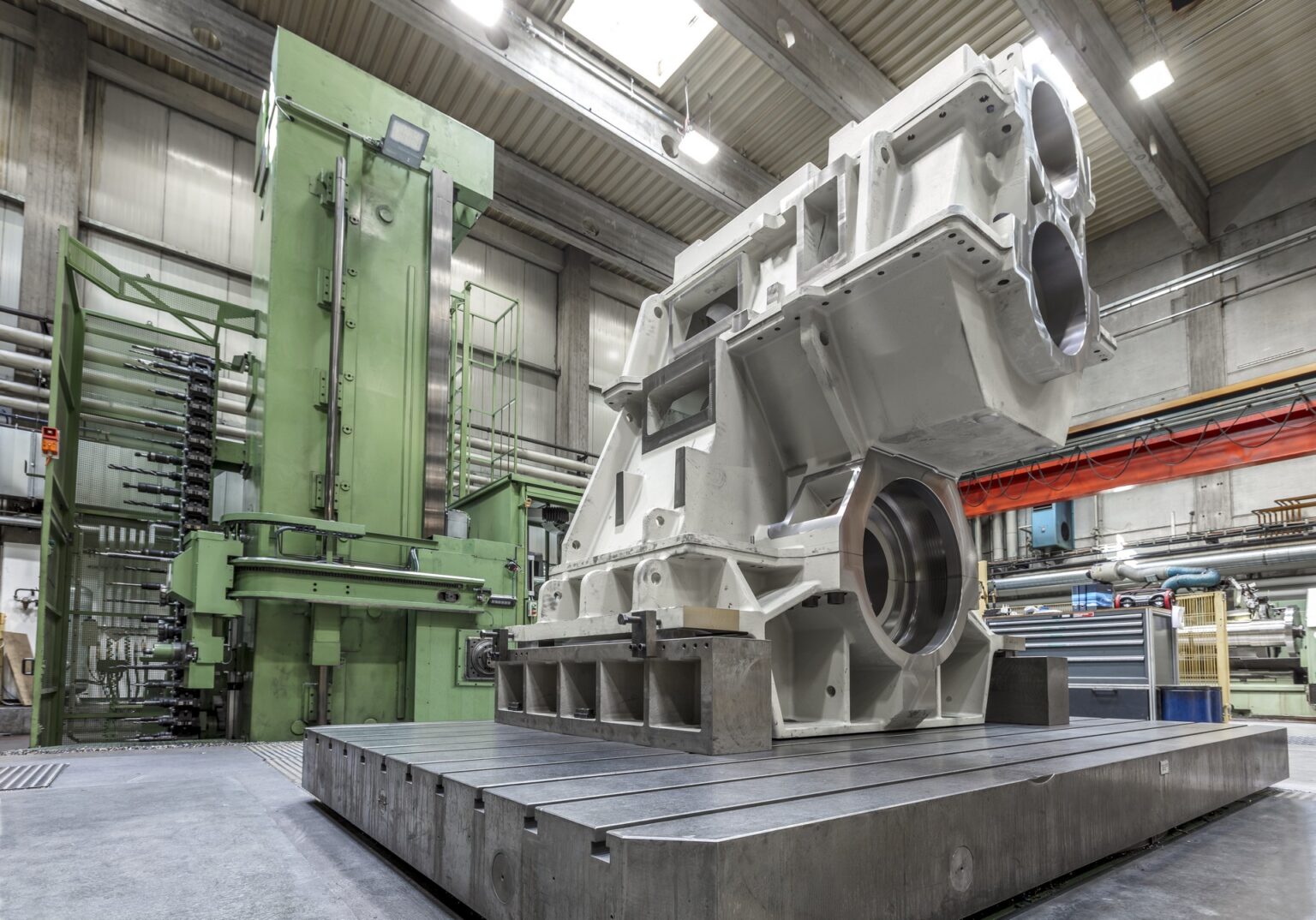

Contract Manufacturing

Components at the Customer's Request

We specialise in maritime propulsion technology. And we manufacture all of our own gearboxes for different types of ships at the REINTJES headquarters in Hameln.

But we can do even more. Industrial drive technology is a second area we cover, contract manufacturing a third.

Contract manufacturing means that we use our machines to produce individual components at the request of our customers.

These can be gears, shafts or complete wheel sets. Specifically, we offer the following contract manufacturing services:

- Heat treatment

- Toothing

- Machining of cubic components

- Other

Heat Treatment

We treat case hardening or tempering steel or nitriding steel as standard.

Case hardening, tempering, annealing:

- Diameter: 2600 mm

- Height/length: 2700 mm

- Unit weight: 12.500 kg

Documentation:

- Case depth

- Determining the mechanical properties

- Heat flow diagram

- Structure evaluation

- Ultrasonic testing

- Etc.

Toothing

We machine external gears by hobbing and profile grinding.

Workpiece diameter:

- From approx. 200 to 3000 mm

Maximum workpiece length:

- From approx. 200 to 2200 mm

Module:

- Up to max. 24

Gearbox quality:

- Standard: Quality 5 according to DIN ISO 1328 (in individual cases up to quality 4 according to DIN ISO 1328)

Separate gearbox documentation:

- Profile

- Flank line

- Division

Test method with determination of:

- Surface hardness

- Surface roughness

- Surface crack examination

- Barkhausen noise

- Etc.

Hirth coupling:

- Customised

Machining of cubic Components

We have a range of three- to five-axis processing machines with plate fields or interchangeable pallets. We use these to process cubic individual parts or small series.

Pallet size:

- 3000 x 4000 mm

Unit weights:

- Up to 30,000 kg

Work area:

- X-axis up to 5000 mm

- Y-axis up to 4000 mm

- Z-axis up to 1000 mm

But that’s not all. Turning, cylindrical grinding, painting, assembly, and gearbox test runs with and without test load are also part of the contract manufacturing services at REINTJES.

Other

Our portfolio also includes the following in the area of contract manufacturing:

- Turning operation

- Circular grinding

- Assembly

- Painting

- Test bed for gearbox test runs with and without test load (for function testing)