Get in touch with us:

+49 5151 1040

info@reintjes-gears.de

Service Hotline

+49 5151 104104

REINTJES GmbH

Eugen-Reintjes-Straße 7

31785 Hameln

Or use our contact form:

Our next trade fair dates

03/10/2026 to 03/11/2026

TTB

Mobile, US

03/25/2026 to 03/27/2026

Asia Pacific Maritime

Singapore

04/22/2026 to 04/24/2026

NN Logistica

Manaus, Brazil

04/22/2026 to 04/24/2026

Sea Japan

Tokyo, Japan

Marine gearboxes in the digital age: REINTJES increasingly focusses on gearbox automation

Shipbuilding is facing a turning point – and terms such as automation, digitalisation and hybridisation are increasingly coming to the fore in this rather conservative market.

The reasons for this are complex and range from the desire to reduce fuel consumption and emissions to real-time data exchange and the development of autonomous ships.

Significant development project

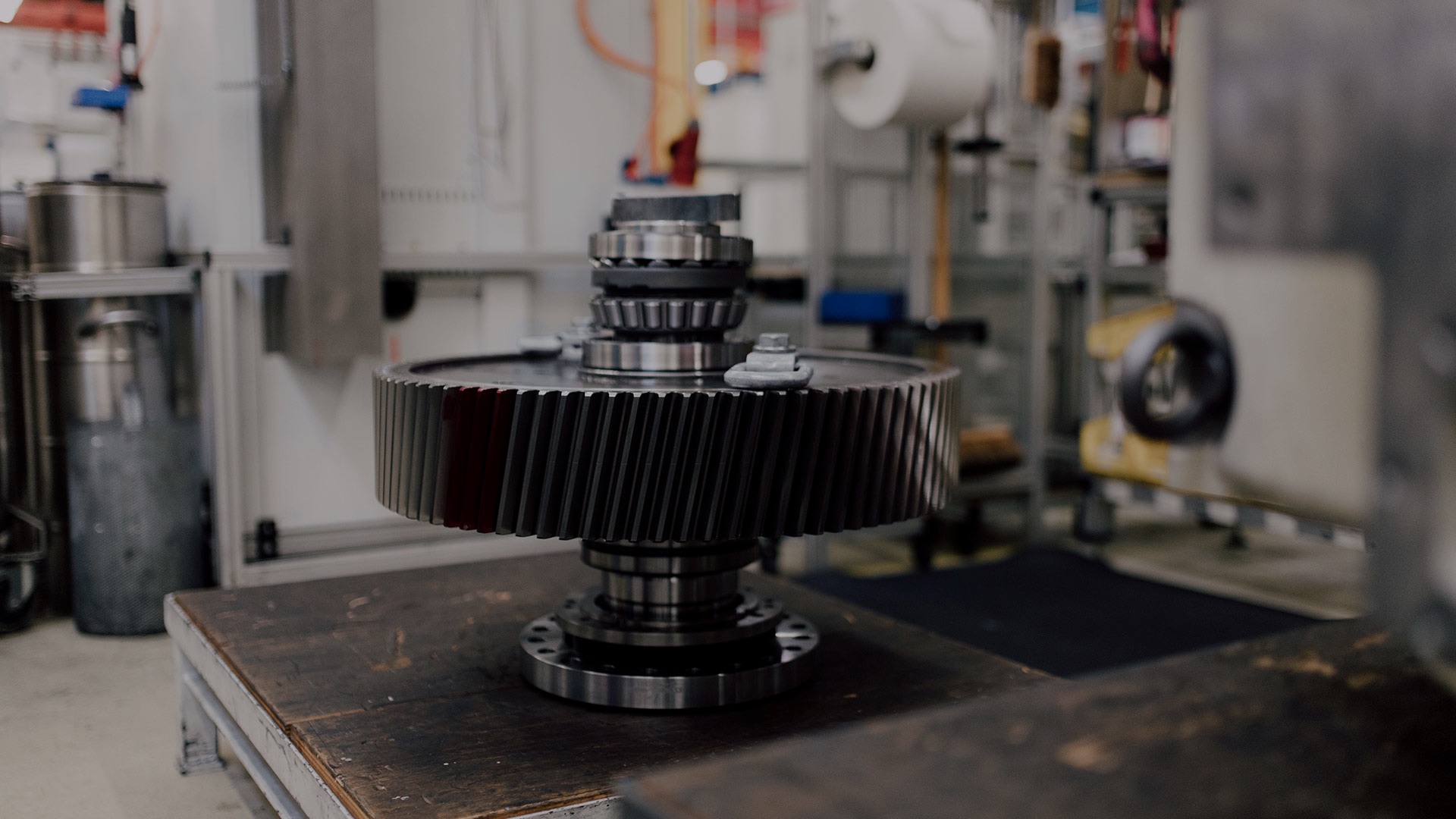

In order to make its own marine gearboxes even more efficient and powerful, REINTJES GmbH has been working on a modern solution in an internal development project.

“Our main goal was to make our gearboxes intelligent, so to speak, and equip them with more functions using a control unit. With conventional hydraulic clutch control, only the basic shift modes “forward” and “reverse” were possible,” says REINTJES CEO Klaus Deleroi, explaining the reasons for the company’s own development work in this area.

The result is impressive: developer Norman-Daniel Klippel and the project team led by project manager Andrzej Sawicki have designed the REINTJES Gearbox Automation (GBX-A).

“This small control unit can do a lot and has been installed directly on some of our gearboxes since last year. As an upgrade, it is basically available for almost all of our gearboxes; in fact, hybrid gearboxes can no longer do without automation,” emphasises Norman-Daniel Klippel.

Gearbox Automation: more than just an upgrade

Gearbox Automation from REINTJES is more than just a simple upgrade. It is an intelligent solution. The GBX-A uses a precise and efficient programmable logic controller to control the proportional valves.

“Engagement is smooth in all areas of application and the hydraulic noise is significantly lower,” says Klippel, reporting on two major advantages that are both noticeable and audible.

But that’s not all. The individual settings as main clutch or auxiliary drive allow flexible adaptation to different drive configurations and operating conditions.

The user-friendly design of the system also contributes to customer benefits, as it facilitates operation and maintenance, thereby reducing the amount of work involved.

“Real-time visualisation of status and parameters allows us to continuously monitor the system and, if necessary, perform remote maintenance or adjust data. This increases operational reliability. And, of course, the customer also has the option of viewing the data,” concludes Norman-Daniel Klippel.

The developer also mentions other areas in which Gearbox Automation is particularly strong: sustainability and efficiency, as well as networking and integration.

“Our GBX-A is energy-efficient and helps reduce fuel consumption and emissions. It also features communication capabilities with power management systems and various integrated interfaces. These enable seamless integration into existing ship systems, facilitating data exchange and centralised control,” says Klippel.

Tool with real potential for the future

With Gearbox Automation, REINTJES is setting a new standard in shipbuilding. Intelligent control of marine gearboxes makes a valuable contribution to more efficient and sustainable shipping.

REINTJES thus emphasises that tradition and innovation go hand in hand on the path to the future of maritime propulsion technology.